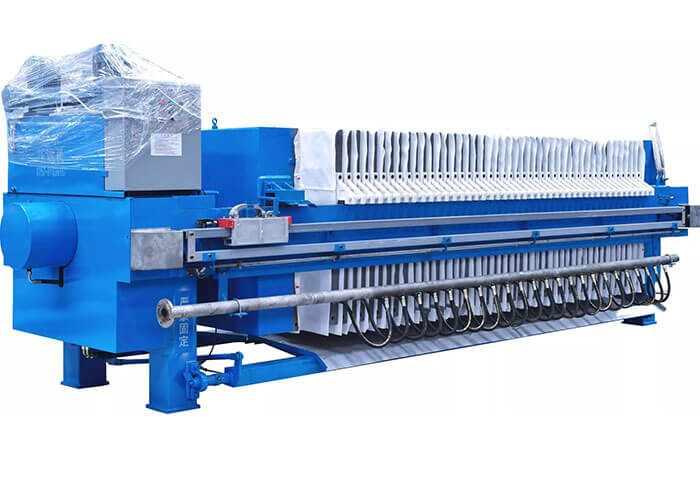

Filter press systems play a crucial role in various industrial processes, particularly in the chemical, metal processing, and waste treatment industries including recycling. Their primary function is to separate liquids from solids by applying pressure to a filter cake, resulting in a drier and more manageable end product or final stage. However, the widespread adoption of filter press systems has significant environmental implications that must be addressed.

One of the primary concerns is the massive amount of wastewater generated by these systems. The filter cakes and liquids discharged during the pressing process contain high levels of chemical contaminants, heavy metals, and other pollutants that can harm aquatic ecosystems. Untreated or inadequately treated wastewater can lead to water pollution, contaminating rivers, lakes, and underground aquifers.

The waste generated by filter press systems is another environmental concern. The filter cakes, often in the form of thick, gloopy mats, contain residues from chemicals, heavy metals, and other hazardous substances. These waste products are often disposed of in landfills, where they can leach toxic chemicals into the soil, contaminating soil and water sources.

Furthermore, the high water consumption associated with filter press systems contributes to water scarcity issues, particularly in regions where water resources are already strained. The use of chemicals and other consumables during the filter pressing process also generates significant amounts of packaging waste and contributes to greenhouse gas emissions during production and transportation.

To mitigate these environmental impacts, various alternatives and best practices can be implemented. One approach is to adopt more efficient filtration technologies that reduce water consumption and organic solvent usage. Filter aid recycling, for instance, can minimize the generation of waste products, while the use of organic solvents can minimize environmental harm.

Another key strategy is to incorporate waste treatment technologies into filter press systems. Examples include biological treatment systems, industrial wastewater treatment units, and other treatment technologies that can safely remove pollutants from wastewater before discharge. Implementing these techniques can minimize or eliminate the adverse environmental effects associated with filter press systems.

Finally, recycling and repurposing materials are essential aspects of reducing environmental impact. Companies can manage waste more effectively through closed-loop systems, where recovered waste materials from filter press operations are reused in other industrial processes. Implementing circular economy principles and waste to product methodologies can minimize waste disposal and reduce the strain on landfills.

While filter press systems are essential tools in various industries, their significant environmental impacts cannot be ignored. By adopting more efficient, sustainable technologies and embracing waste reduction strategies, facility operators can minimize environmental harm frame and plate filter provide a healthier environment for the community and their bottom line.

Leave a Reply